As bicycle technology evolves, mechanics are facing more and more challenges that make their job more complex and time-consuming. An almost unmanageable number of components and different standards between the various shift group levels are just a few reasons why the groupset market has become a very challenging environment. Additionally, for both dealers and manufacturers, there are higher requirements for mounting the different parts. This is a trend that is further magnified by the increasing use of electronic components.

Improved performance and a simplification

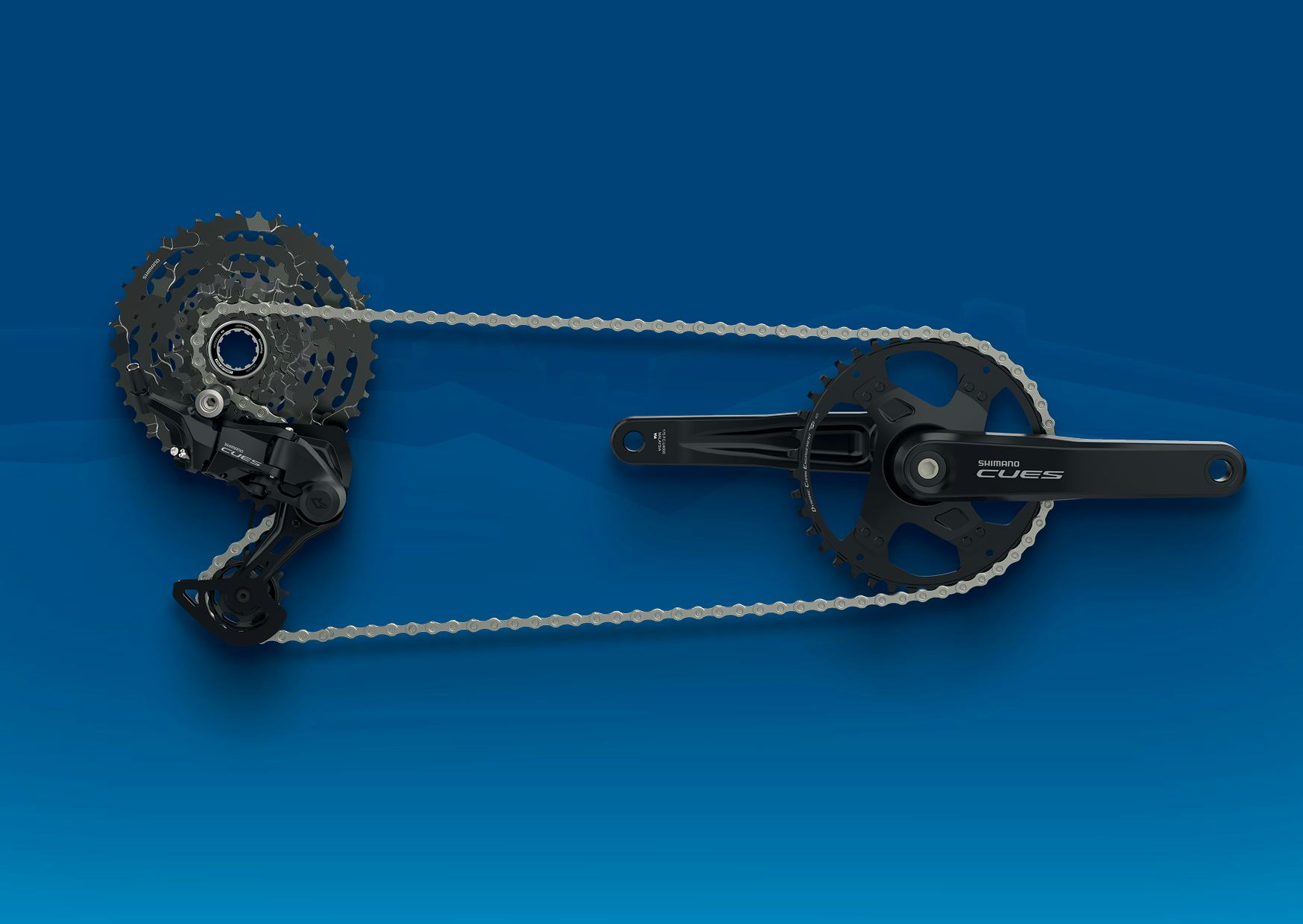

With the new CUES ecosystem, Shimano wants to change that. The goal: better shifting performance on the one hand, and greater cross-compatibility and a simplified supply chain structure on the other.

“By consolidating our 9-, 10-, and 11-speed component ranges with interchangeable components, including common derailleur pulleys, cassette sprockets and chains, Shimano CUES reduces shop inventory needs and simplifies the servicing process for mid-tier bikes,” explained Mattia Montalbano, CUES marketing manager at the Shimano Europe headquarters in the Dutch city of Eindhoven.

“The impact of this new technology will be felt widely across bike manufacturing and retail levels, bringing stability to stock levels and a more cohesive approach to a product ecosystem that is made up of many different components and product names into one unified and compatible system,” he noted.

The focus of the new CUES system will initially be on the MTB and trekking segments”

Interchangeable parts

A look at the current Shimano line-up below the 105 line shows exactly what Montalbano means. With Tiagra, Sora, Claris, Deore, Alivio, Acera and Altus, seven different product categories are mostly used on entry-level and mid-range bikes. These will be replaced by only three 9-, 10-, and 11-speed groupsets in the CUES system, where many parts are interchangeable.

The focus of the new CUES system will initially be on the MTB and trekking segments. “These groups have a huge market share. Therefore, with our new approach of simplifying things, we can also create the biggest impact here,” says Montalbano, who also believes that the introduction of CUES will have a positive influence on the future of bicycle design. In doing so, he refers to, among other things, simplifying engineering, logistics, and mechanical work. “It will be much easier for manufacturers because they can design different bike models without having to consider varying component specifications.”

CUES is the future

Following the launch of the CUES system in March, Shimano expects the first products to become available in the fourth quarter of 2023. However, Montalbano also reveals that Shimano CUES is the beginning of a long-term project based on a multi-year plan. “We will, of course, continue to support the current groupsets, but we see CUES as the future.”

This article is sponsored by Shimano.