Drivers increasingly identify with the light electric vehicle (LEV) they’re riding. Using a LEV – whether it’s a bicycle, moped, cargo bike or scooter, is no longer just a functional means of transportation. For a growing number of people, it’s a way of life: young urban parents on cargo bikes or commuters on a high-speed bike being some examples.

This trend is fed by the worldwide emergence of new players and business models in the field of micro mobility and companies that promote themselves as a lifestyle brand. They anticipate their customers desire to identify with their vehicle, making the aesthetics of a vehicle more and more important for the distinctive character of a brand.

Stepping away from the 'form follows function' principle

Of course, there has always been a certain interest in aesthetics in the design of bicycles, but the available construction techniques did not allow much room for creativity and experimentation. The construction was limited to the moulding of tubes in a geometrically and ergonomically correct way. Therefore bicycle design leaned towards the ‘form follows function’ principle. An industrial design style in which functionality is dominant over aesthetics. For a long time this practical but slightly plain style was generally accepted by the market.

For a growing number of people, it’s a way of life: young urban parents on cargo bikes”

Nowadays a bicycle doesn’t have to exist out of thin steel tubes, with a relatively small diameter, brazed together with lugs. New production techniques and materials make it possible to be more creative with the design. The introduction of aluminium frames made it more common to use larger frame tube diameters, which increased with the launch of composite frames. The integration of components such as the battery, controller and cabling enlarged the frame tube even more. Gradually it became accepted to use more volume in bicycle frames, making it possible to create unique and aesthetically pleasing designs.

New production and material trends

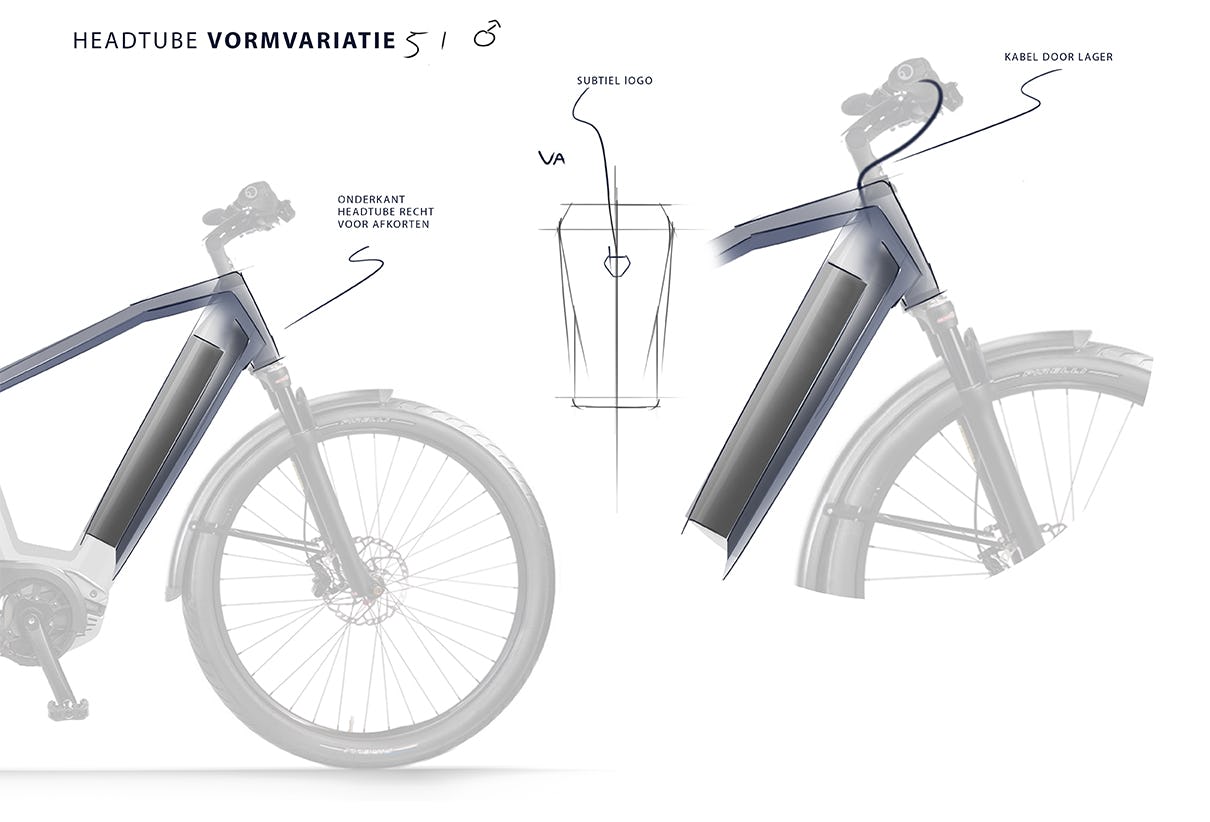

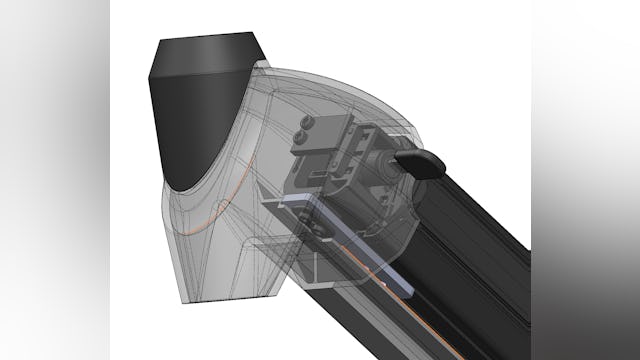

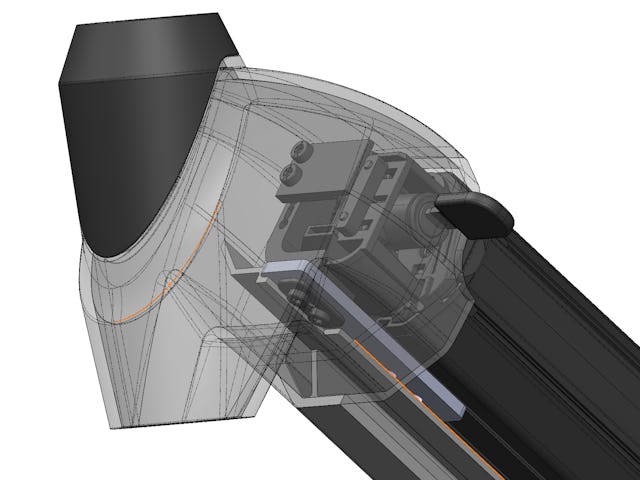

A more recent trend in bicycle frame production is the use of precision casting techniques, which brings even more volume and – more importantly- freedom of form into the design. This lost-wax production method has been used in the car industry for years. The technique is suitable for the construction of precision parts that need to endure a lot of force. This technique is now embraced by the bicycle market and used by multiple brands.

Another development that ameliorates the aesthetics and distinctive character of LEVs is the use of larger body panels and surfaces. This is seen in closed and semi-closed vehicles, such as electric tricycles, quadricycles, and cargo bikes. With these products it’s not the frame, but the exterior. With cargo bikes, for example, this trend is visible by the use of the well-known EPP foam boxes and the form freedom in which they are designed.

New opportunities come with new challenges

The emergence and acceptance of new materials and technologies enables designers to step away from the ‘form follows function’ principle. Production methods such as aluminium hydroforming, carbon frames and 3D printing give the bicycle industry the opportunity to experiment with forms, patterns and lines over the surfaces.

Within the automotive industry, this way of designing is referred to as ‘surface entertainment’ and it offers designers an almost unlimited freedom in their outlines. It also offers a new challenge: when used in moderation surface entertainment enhances the aesthetic appeal of a vehicle, but when it’s exaggerated it can become a turnoff. The correct use of these new designing possibilities is a refined play in knowing what to add and what to leave out.

Distinctive and aesthetically balanced design

Let’s bring e-mobility to a higher level”

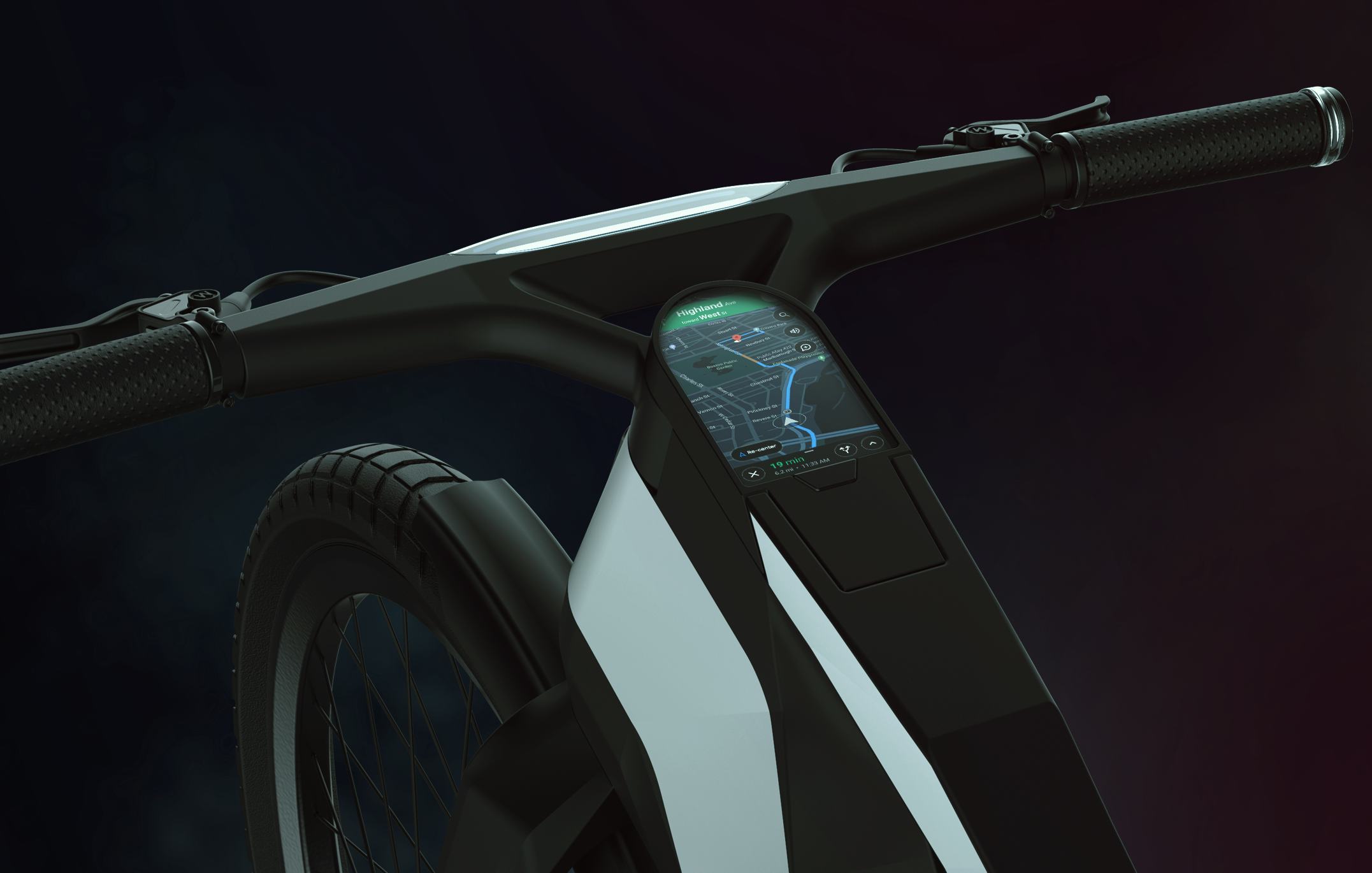

VROEGH Design, a design agency from the Netherlands, can help with these challenges. They are specialised in the development of LEV’s and can assist both existing brands and promising startups with the development of their products. Besides their e-bike and cargo bike expertise they use designing methods, materials, and production techniques from the automotive industry for the development of e-bikes and cargo bikes. This results in vehicle designs that are distinctive and aesthetically balanced.

The independent design agency works as an external R&D department and takes care of the activities related to engineering and innovation. Since the agency is completely specialised in Light Electric Vehicles, it has all the expert knowledge to develop and integrate the mechanic, aesthetic, and digital experience of a vehicle.

Exciting times for e-mobility

The trend of cyclists identifying with their vehicle, limitless designing possibilities and a worldwide interest in bicycles bring great opportunities for mobility brands. The growing demand for aesthetically appealing and balanced design combined with the development of new techniques and materials, makes the e-mobility market such an interesting place to operate.

Not only is there an increasing interest in e-bikes and cargo bikes, all sorts of e-mobility products are in demand. Electrical mopeds, last mile solutions and high-speed bikes all respond to the idea of mobility as a lifestyle. VROEGH Design welcomes these events with great enthusiasm. Let’s bring e-mobility to a higher level, making an e-bike the status symbol of the 21st century!

This article was sponsored by VROEGH Design.