One of the founders of Faction Bike Studio is Erick Auger. For years, he worked as a product engineer and R&D manager in the bike industry. After three years of working for a consultancy company, he founded Faction Bike Studio in 2010, together with an industrial designer.

I saw technical gaps between the smaller and bigger bike brands ”

“I saw technical gaps between the smaller and bigger bike brands. My idea was: I love designing bikes and want to offer my knowledge and experience to the relatively smaller companies. We started designing projects. Our first customer came from South Africa, the second from Spain. Very quickly we grew and exported our expertise.”

Currently, Faction Bike Studio has clients of all sizes in North America, Europe and they are manufacturers of bicycles, components and accessories. “Our projects focus on both high performance downhill bikes and typical Dutch commuter bikes, so a very wide range. We have a good mix of companies with high-end and low-end products. E-bikes have a significant share."

"Today, 70% of our projects involve e-bikes that we engineer and design. There is increasing demand, especially from the micro mobility sector. The companies in this segment are more technologically oriented than bicycle experts”, says Auger.

“What makes us unique compared to other design studios is that we focus entirely on bicycles. That can be frames - the majority of our work - but also components and accessories. If desired, we do the entire process. Or we help our customers with small, specific needs. With our staff, many of whom come from bicycle manufacturers, we are also very good at helping with marketing strategies for new products. We offer a wide range of services: we come up with ideas, make sketches with industrial designers and carry out preliminary studies with engineers. In addition, we deal with 3D modelling, virtual simulation, drawings and the prototyping and testing phase.”

Confidence

It is the creation of prototypes that make the difference at Faction Bike Studio. During each phase of the development project, the Canadian company offers a prototype. “Especially during the corona pandemic, we saw that factories in Asia were not always able to do that anymore for customers. Or only at a very late stage, when the product was almost already in the pre-production phase. We very quickly saw the added value of a good prototype and therefore invested in being able to do this for customers.”

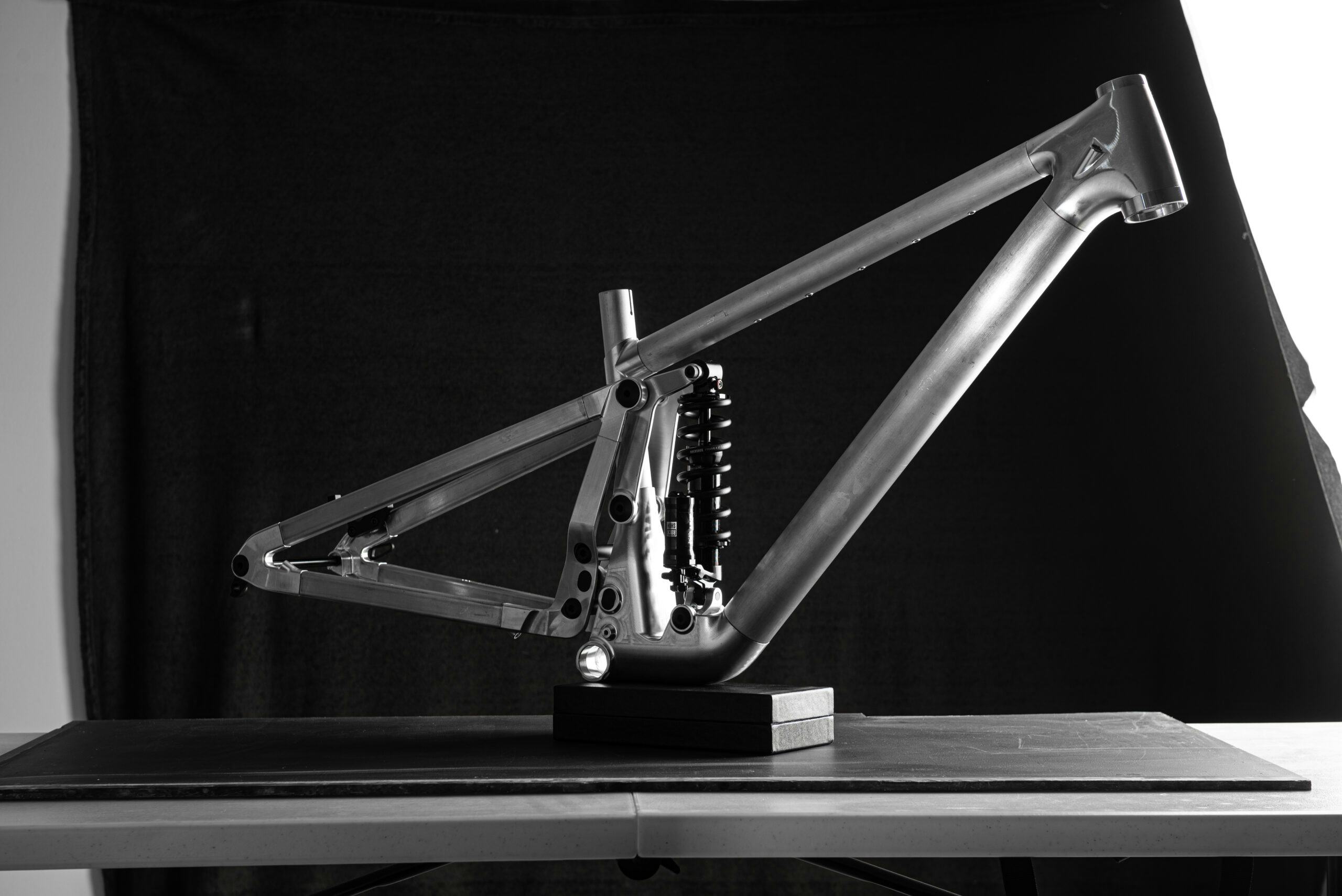

There are two main categories of prototypes. One is about innovation and technology. Sometimes a company develops a specific, progressive technology that is built into a bicycle. Think for example of a new suspension for a mountain bike. This also involves intellectual property and patents. Secondly, there are various types of prototypes of a total product. First there is the prototype, made with the 3D printer, for example to check compatibility. The second prototype is a rideable test mule in steel or aluminium. The look and the weight aren’t perfect but it’s useful to test geometry and usage. The third prototype, the performance one, is lightweight and is used to validate ride feel and speed and performance. That lets you experience how the bike actually feels.

Making prototypes has numerous advantages. “If you are working on innovations, then it brings risks if you don't have prototypes. A lot of bike brands are now looking at internal storage in the down tube, for example. It is something new, so you want to be sure that your technology works. Preferably at an early stage," says Auger.

"We have data acquisition instruments that we put on the prototype bike during a test. We use them to obtain data on the new idea. We share the results with our customer.”

Problems that are identified early on prevent unnecessary tooling investments. “Sometimes a problem only appears shortly before mass production. At that point, major tooling investments have already been made,” says Auger.

“The prototype service is a good way to build trust. And for us as a company to work on a partnership. Customers trust us when building new bikes. They can hold and ride something thanks to the prototype service. Computer files and drawings in emails are nice, but this is something concrete.”

The prototype service is standard when it comes to new technologies and innovations. The investment in prototypes pays off.

“It’s more expensive if you find out during the pre-production model that things are not right. In addition, prototypes shorten lead times; you can enter the market and sell sooner. Another advantage is that the prototypes help you to build a marketing story. You show the work behind the scenes. What obstacles you encountered, what you adjusted. How you made a better product. This is a big asset in the marketing campaign.”

This article is sponsored by Faction Bike Studio.