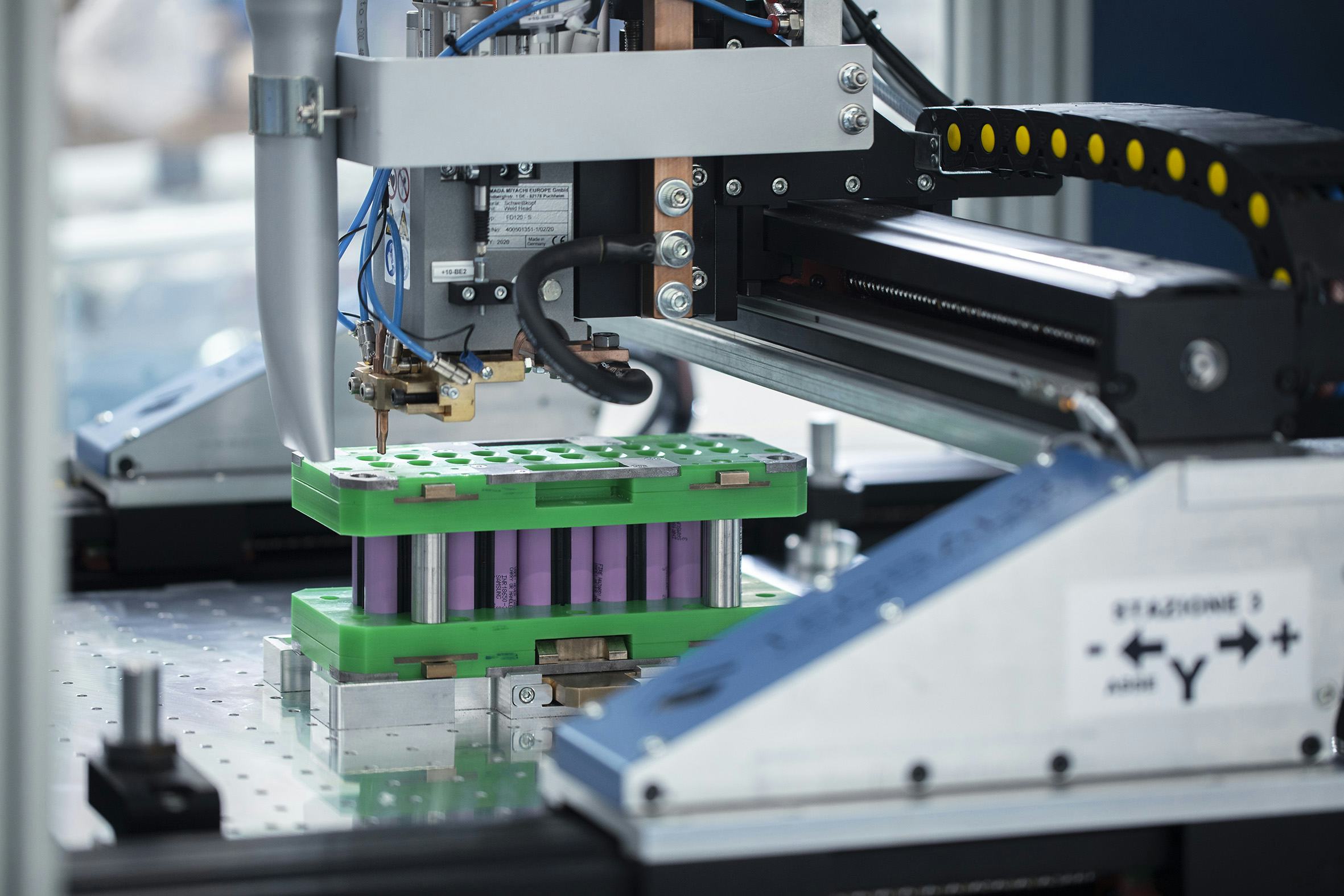

XENER is a division of Atex Industries, a company specialized in the electronic design and production for B2B the market. The company invested in modern production lines for lithium batteries for pedal assist bikes and more generally Light Electric Vehicles (LEV's), promoting itself as a technological advanced and reliable partner for e-bike manufacturers.

How batteries add value to e-bikes

In an extremely competitive market such as e-bikes, focusing only on green is not enough anymore. In order to generate added value, e-bike brands should develop Unique Selling Proposition strategy.

In an extremely competitive market such as e-bikes, focusing only on green is not enough anymore. In order to generate added value, e-bike brands should develop Unique Selling Proposition strategy.

The XENER team is made up of highly qualified engineers, who work closely with bicycle designers; this allows us to translate the needs of our customers to high performance products in any conditions of use. Thanks to the exclusive use of high quality cells - from selected suppliers - we can offer a warranty on the batteries for their entire life cycle.

In order to meet the needs of e-bike manufacturers, we not only produce the battery pack, but we also design and develop the hardware and software for the Battery Management System (BMS). Therefore, XENER batteries become tailor-made.

In this way we integrate the most current Internet of Things (IoT) technologies to e-bikes, allowing predictive maintenance, providing the possibility of access to the world of smart mobility and adding value to the product, making it more competitive.

Side by side with the customer

The e-bike battery must communicate with the outside world and with the various devices in the system through a shared protocol; this is why it's essential to rely on a partner which is an expert in the design and production of this product.

The e-bike battery must communicate with the outside world and with the various devices in the system through a shared protocol; this is why it's essential to rely on a partner which is an expert in the design and production of this product.

XENER provides consultation and technical support: it understands the customer's needs and translates them into exclusive electronic solutions.

Through prototyping and collaboration with accredited laboratories for certifications (EMC, 621333, CE, UL, and UN38.3), we guarantee high quality standards and accurate product control at all stages of production.

The entire XENER production is made in Italy and can reach 200,000 pieces per year, thanks to the modern equipment for the automatic assembly of the SMD and PTH components of our BMS.

All batteries are equipped with safety access, with PIN and remote control for after-sales predictive service. They are tested and linked to a unique QR code, which contains all the steps of the battery production cycle and which guarantees its traceability.

Hi-tech partner for e-bike batteries

XENER promotes itself as an innovative partner for the e-bike sector, as part of the Atex Industries Group. The company makes use of the know-how deriving from the experience gained by the Group in more than 50 years in the electronics sector to develop battery packs and controllers with a high level of performance of the drive system and with a greater charge and discharge speed.

XENER promotes itself as an innovative partner for the e-bike sector, as part of the Atex Industries Group. The company makes use of the know-how deriving from the experience gained by the Group in more than 50 years in the electronics sector to develop battery packs and controllers with a high level of performance of the drive system and with a greater charge and discharge speed.

XENER has decided to operate in the lithium-ion battery sector: in agreement with the e-bike manufacturers, they want to contribute to the energy transition by reducing CO2 emissions.

This article is sponsord by Atex.