Circu Li-ion, founded in 2021, developed the upcycling process of electric vehicle batteries to support the high volume of redundant, used batteries since the rise of e-bikes on the European bicycle market. By developing a fully automated process, the company says it can handle large volumes of batteries. Also due to a universal dismantling process they can treat a range of different batteries.

The upcycling process

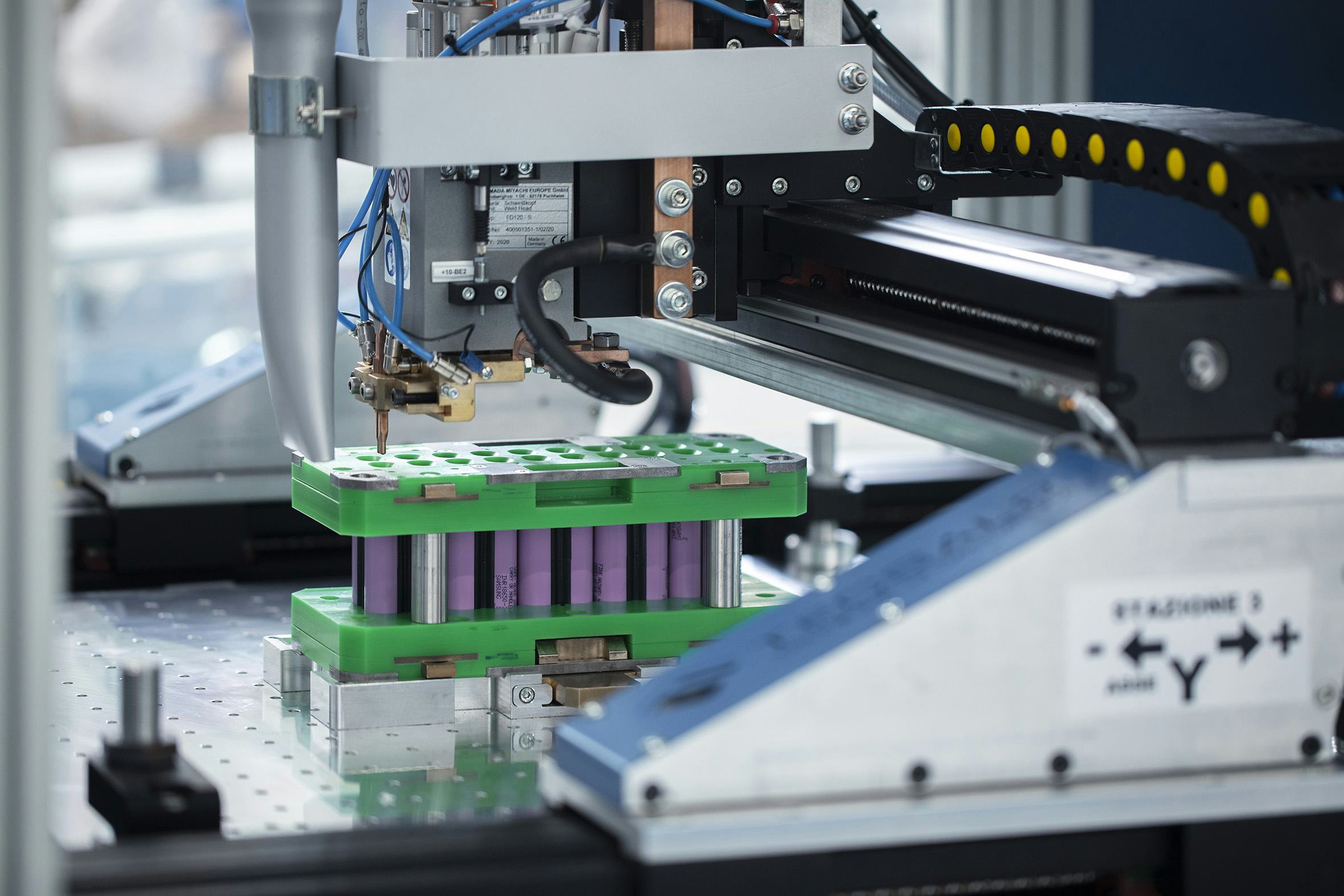

The start-ups mission is to offer a technology to enable the upcycling of batteries on an industrial scale. “We do so by automating the disassembly of used battery packages, the identification of the functioning battery cells, and the reassembly into new battery packs or other energy storage systems,” explains CEO Antoine Welter. “For the parts of used battery packs that cannot be upcycled, our approach also enhances existing recycling processes by separating components before they are shredded into black mass.”

“With our technology, we provide companies that have a high volume of used batteries the possibility of reducing their carbon footprint and their operating costs, by turning their used batteries into ones that have almost the same charging potential as new ones. Potential clients can either opt for a Machine-as-a-Service solution where the machine is installed on-site or for a service-only solution where the upcycling takes place at a third-party service provider’s site.”

Government backing

The first development phase of Circu Li-ion’s Machine-as-a-Service technology has been successfully closed and the company reports that the second phase is currently on-going. The founding team raised a seven-figure pre-seed financing round from successful business angels from all over Europe and was selected as one of the participants of the start-up acceleration program, Fit4Start, which is backed by the Government of Luxembourg.