The most popular cells used in e-bike batteries are 18650 and 21700 form factor with NMC chemistry. More and more batteries are using bigger cell sizes, for a few important reasons. Chief among them is the fact that less cells are required to reach the desired capacity. To achieve capacity of close to 10 Ah in the 18650, three cells connected in parallel are needed, while the 21700 will require two cells. The difference in mass is not negligible – the weight of 18650 cells in configuration 10S3P is about 1.5 kg, while the 21700 in the 10S2P configuration with similar energy is about 0.1 kg lighter. In a battery with higher voltage, the difference is larger.

Also, the largest theoretical nominal capacity for 18650 form factor is 3.5 Ah, while for the 21700, it’s 5.0 Ah. Nowadays, the maximum gravimetric energy density for NMC chemistry is 250-260 Wh/kg. Cells with a larger capacity have been announced, but only in the 21700 size. The target is to achieve 5.5-5.65 Ah, and perhaps even up to 6 Ah, which will allow the extension of total battery capacity or cycles, after reducing the voltage range. Currently, suppliers are looking to use new elements in cells, such as silicon, to achieve higher capacity, as well as sodium to optimise cost.

Mechanical optimisation

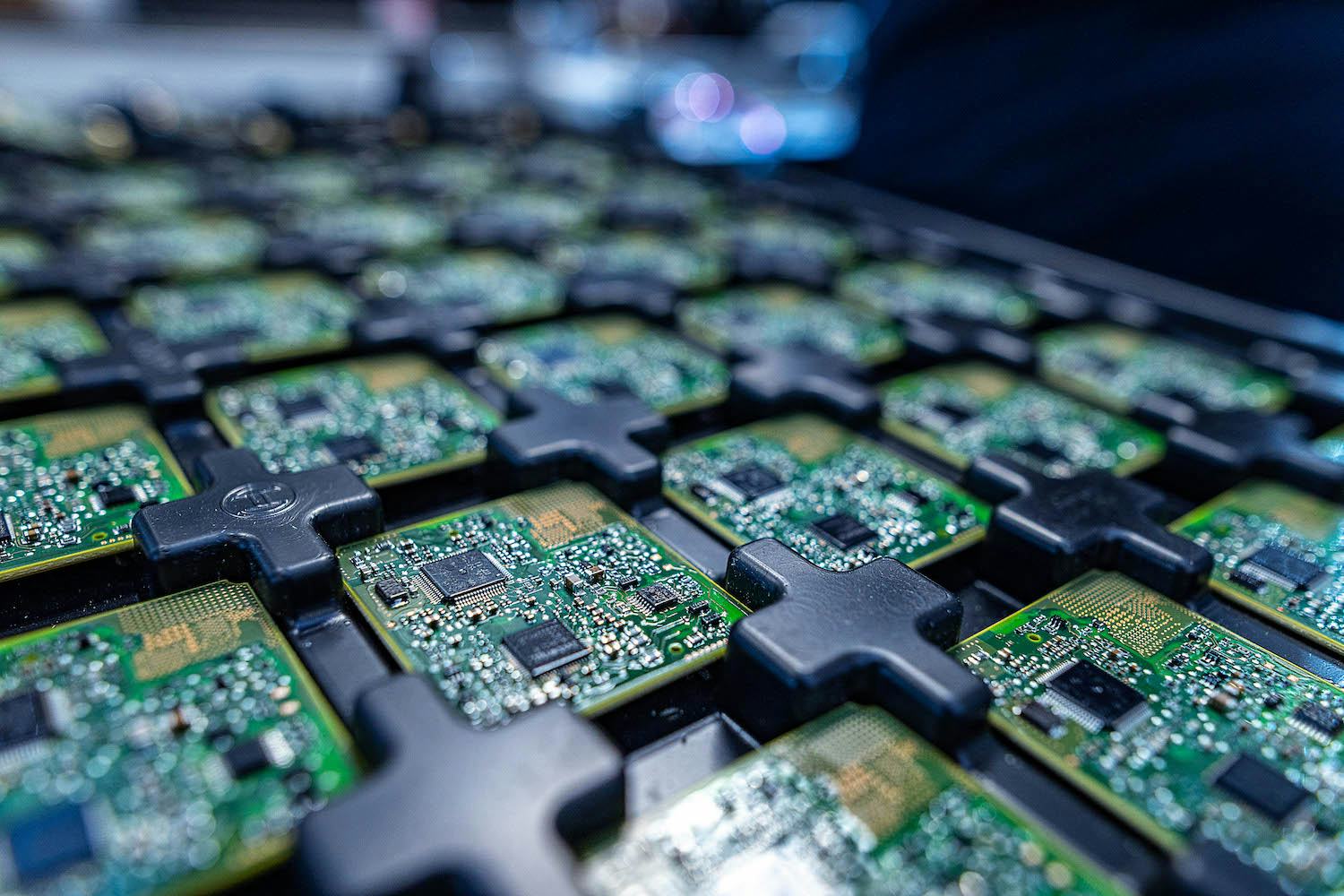

Every mechanical part adds to a battery’s weight and size. Integral batteries, which are hidden in the frame, very often have a block module construction. One block contains top and bottom cell holders and 4-10 cells connected in proper configuration and connectors with terminals to connect to the next section. There are usually also additional insulation, busbars, or wires, which cause hotspots and a voltage drop.

The placement of cells transverse to the longest axis only requires two cell holders, with current flowing through just the cell connectors. Additional BMS can be mounted on one side of the corepack with easy access to every voltage point, ensuring wire sets are not required. The battery is lighter as it contains fewer components, plus assembly is easier and faster.

The housing also has a significant influence on the weight. Currently, the most popular materials used are aluminium and plastic. But using carbon fibre should decrease the mass of the battery, although this does add cost to the construction.

Currently, European regulations are moving towards making batteries more repairable and ensuring they have long lives, to reduce environmental impact. Therefore, new batteries are likely to be easier to repair by third parties.

BMS functions

Nowadays, battery management systems are more complex devices with various functions. Almost every BMS in e-bike batteries contains functions such as:

- CANBus used to allow communication between all electronic e-bike components and the information exchange.

- State of Health (SoH) algorithm, which is helpful when considering the rate of degradation of the battery. Typically, a battery with 80% of initial capacity is considered EoL (End of Life).

- State of Charge (SoC) algorithm is used to estimate the range of an e-bike. Currently, there are algorithms based on cell voltage, temperature, state of health, current flow, and more to increase the precision of the SoC indicator.

- State of Power algorithm, which is used to inform the motor controller about the maximum current that can be drawn from the battery at any one time, ensuring best performance, especially at a low state of charge.

- Additional outputs for use with items such as lights, phone chargers, and GPS modules.

What’s more, BMSs are now safer than ever before. They’re equipped with double protection, plus they contain elements such as Failure Mode and Effect Analysis (FMEA) and safety functional analysis.

Next year, safety standards for lithium-ion batteries will be extended. For example, there could be a gas sensor mounted on the BMS to detect potential cell rupture, or an accelerometer to switch off the battery outputs should an accident occur.

What’s more, we are likely to see the use of smart technology soon, such as Bluetooth connectivity, as well as end-to-end communication encryption for extra safety. Smart modes could also be used to prolong the service life of the battery, by limiting the SoC and maximum power, for example. Changes to European regulations are almost certain to also force other changes, such as open access for third parties to some BMS information.

Smart charging

Charger manufacturers have added new features to their off-the-shelf solutions in recent years. Currently, battery and charger communicate through an additional bus. This increases safety, as critical parameters such as voltage and current are measured by both parts of the system and can be compared to one another. If the difference is significant, charging is stopped as a failure is presumed. A smart charger can charge to limited voltage to extend life cycle. If we want to store a battery for a long time without use, it’s possible to charge the battery to 50-60% SoC to reduce natural degradation of cells.

Fast charging is a trend, thanks to the increase in maximum charge current. Previously, this was typically 0.5C, but it’s now closer to 1C, allowing for a faster charge time. But fast charging decreases a battery’s life, meaning a compromise is needed. For example, maximum current could be used to reach 80%, before then switching to standard current.

Types of e-bike batteries

E-bike batteries can be divided into four groups:

- Low energy, up to approximately 360 Wh

- Mid energy, approximately 360 – 700 Wh

- High energy, more than 700 Wh

Low energy batteries are generally slim and light, plus they are almost invisible when built into the design of an e-bike. The system often works with a range extender. A drive unit must have power limitations because battery voltage will drop under load (information about SoP is crucial).

High energy batteries are used to ensure a long range and current reserve for overloading the motor. Typically, these are mounted to off-road bikes where power is critical. These batteries need to be charged with a high current charger to achieve a reasonable charge time. This is the most expensive type of battery. A new trend for batteries of this type is configuring a battery in such a way that it will look slim from the side, but will be wider and longer to keep the capacity high.

Medium energy batteries are a compromise between size, energy, and price. The market is currently saturated with mid energy batteries, so manufacturers are looking for opportunities to innovate, to differentiate themselves from competitors. But currently, most new trends are focused on the other two types of batteries.

LFP cells in cargo bikes

LFP chemistry offers a longer life than NMC chemistry, plus it is durable. This makes it the appropriate chemistry for cargo bikes, as they’re for work, not leisure. What’s more, they offer increased safety when compared to LFP chemistry. On the downside, energy density and nominal voltage are both lower, meaning the battery must be larger and heavier.

The target for manufacturers is to develop LFP cells with energy density similar to NMC cells. This will allow them to be used for more and more applications, including, at some point, standard e-bikes used for leisure.

This article is sponsored by EMBS.