The experience of manufacturers of mechanically welded structures makes it possible to meet this demand for e-bike frames. The know-how has been gained over the past 50 years as suppliers of the light mobility industry, especially the two-wheeled sector.

Adapting

In these circumstances we find that the production processes to meet the high demand for e-bikes are very well defined, although a joint development will be necessary between the bicycle manufacturer and the supplier to adapt to the requirements of a welding type that meets the needs of e-bike brands.

Transformation processes

Companies such as Derivados del Motor carry out all the transformation processes in their facilities. These processes begin with the purchase of the raw materials and measurements of pipes and metal sheets, and finish with the final frame.

11 Steps

For a better understanding of the production process, we define all the necessary steps from the arrival of the raw material to the end product, according to the manufacturer's specifications.

1. Industrialisation and development of the project

The first thing to consider is to have all the technical information of the project to determine the best strategy for the development of the tools and to meet the requirements without forgetting to make an adequate tooling and product costs.

2. Tooling and prototypes

Once the industrialisation has been approved, the necessary tools are manufactured. This will allow engineers to do all the mechanical tests and to ensure that the geometry and resistance tests are in accordance with European regulations.

3. Manufacturing processes

At this point of the process, all the industrial operations required for the mass production of the previously designed and tested frame must be defined.

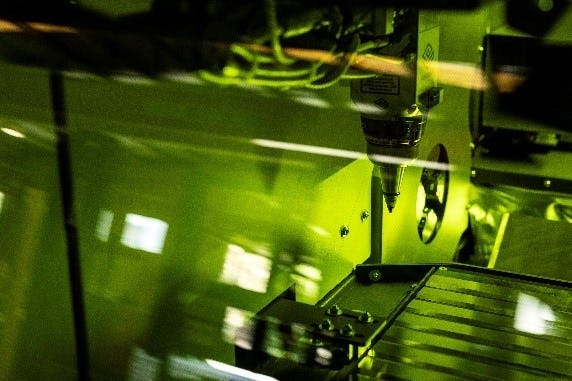

4. Laser cutting of sheet metal and tube

The first step in the production process of a frame is the sheet and tube cutting, according to specifications previously defined in the industrialisation. This will allow us to have the necessary cut for the construction of the product.

This is currently possible thanks to the availability of highly efficient laser cutting machines, ensuring the required measurements with a thorough control of the technical department with high-capacity software.

5. Tube bending

The next step in the production line is the curvature of the pipes in their different sizes and thicknesses according to the requirements of axes and radii curvature previously defined.

6. Stamping / Deep drawing

Like pipes, sheets must be handled to give them the required flat shapes. This will allow us to achieve the manufacture of the final set.

7. Machining process

As in any industrial process, guaranteeing the dimensions or measures and tolerances is essential, so everything can be assembled and welded correctly in the final set. To do this, the use of milling machines and CNC lathes achieves the desired final assembly design.

8. Welding process

After the these processes, we move on to the welding processes. Using the proper tools allows us to weld the frame.

In companies such as Derivados del Motor, that are specialised in different materials such as steel, aluminium, titanium, and their different compositions, we can find several welding strategies that depending on the technical requirements and production volumes will carry out this work in robot welding stations or in manual welding stations.

9. Sand blasting

Prior to the painting process, there is the sand blasting process. Apart from being a previous step for correct priming, it allows to detect those small marks and scratches, remove these, and ensure that the finished surface will be the one that manufacturers and users want.

10. Heat treatment

In projects where aluminum is requested for the construction of the frame, the correct planning of the heat treatment will ensure that any deviation of the structure is avoided, and the designed geometry is reached.

11. Quality control

Although quality control is continued from the receipt of the material and is established in all processes, a final check of the geometry, measurements, and quality of the welding seams is an indispensable requirement. It ensures that the heat treatment has not caused any deviation in the frame structure.

Today, the manufacture of this type of product involves high-level planning with the corresponding supply and purchase management. Planning allows to give all the necessary resources to each of the production departments involved, which are as necessary and essential as the welding itself.

This article was sponsored by Derivados del Motor