Make product offer unique with unique batteries

Product differentiation has become a key success factor in the fiercely competitive e-bike sector. Whether you are motor manufacturers, electric bike designers, assemblers or distributors, batteries are key components that can make all the difference, for better or for worse. Distinctive battery design, ultimate power performance, innovative electronic management and connected services are key topics of interest. On the battery technology side, higher density electro-chemistries, new cell form factors and suppliers coming from the automotive industry provide new opportunities to be considered.

Secure battery supply chain with European sourcing

The automotive sector concentrates the attention of the whole battery cells industry. It will be years before the European battery gigafactories are up and running to satisfy the car manufacturers’ demand. In the meantime, and probably long after the relocation of battery cell production close to final markets, reliable Li-ion cell sourcing from Asia will remain the common rule. This will be achieved through diversified cell supply sources from a range of top quality battery cells suppliers. Independent cell qualification and continuous quality control, warehousing and production lines in Europe will be key to guarantee reliable and high quality deliveries with 100% traceability.

Be at the forefront of the sustainable mobility revolution

Announced in late 2020, the new European Battery Regulation will replace from 2022 onwards the current Batteries Directive. Among the topics under discussion are the inclusion of carbon footprint reporting, minimum electrochemical performance and durability, reinforced safety requirements, eco-design methodologies for repair, removability, reuse and second life, digital battery passport for full traceability… As battery specialists, easyLi’s teams are closely monitoring these developments and are here to share views and start working on next battery generations.

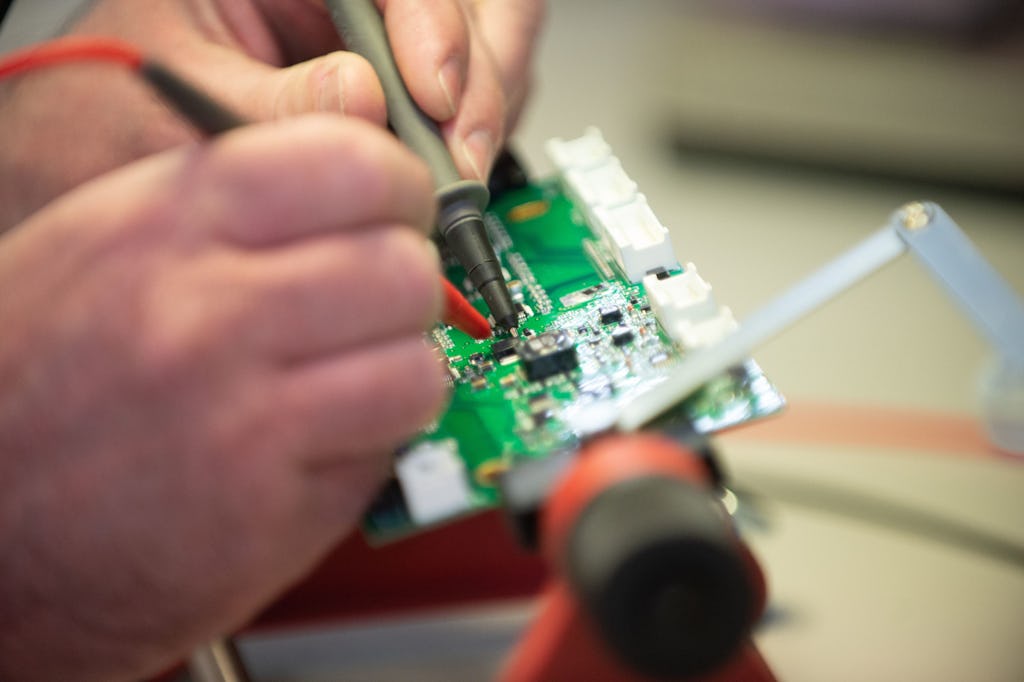

Experience of over 50 years in the advanced battery industry

easyLi Batteries a European specialist of custom Lithium-ion batteries for electric mobility will celebrate its 10th anniversary in a couple of weeks and is ready to be part of the European battery revolution.

With headquarters located at equal distance from Paris and Bordeaux, easyLi has served the micro-mobility industry from its inception in 2011. Millions of Li-ion cells of any shapes and any technologies (NMC, NCA, LFP) have been processed in their French workshops and delivered all over Europe. Apart from being a 100% independent European company, what makes easyLi special is its comprehensive one stop shop offer: technical consultancy, co-construction of battery specifications, in-house prototyping, validation, certification, manufacturing, JIT deliveries, repair and upgrade over product life, on-demand recycling management and reporting…

This article is sponsored bij Easylibatteries